Super Strong Sintered NdFeB Magnet Ring and disc

| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Delivery Time: | 30 Days |

Basic Info

Model No.: GWM-237

Additional Info

Packaging: Pallet with carton

Transportation: Ocean,Land,Air

Certificate: ISO9001:2018,ROHS,REAC

Port: Shanghai,China,Shenzhen

Product Description

I. Anisotropic sintered Neodymium multipole rings

Neodymium magnet is mainly made of Neodymium, Iron and Boron. Neodymium magnet is offered in range of operation tem 80ºC to 220ºC. A sintered Neo magnet has high remanence, high coercive force, and is easily formed into various sizes and shapes. The magnet is suitable for being used in DC Motor, Brushless motor , Speaker, MRI and others.

Features :

Since NdFeB magnets easily corrode, it is often coated to protect against this. Traditional coatings are Nickel, Zinc, and Epoxy with other options available. Selection of a coating should be discussed early on in the design and application process. Sintered NdFeb canbe made in Arc, cylinder,ring and some irregular shape.

A: -High magnetic performance, with the radial maximum magnetic energy product of ring magnet reaching 240~360KJ/m3.

B: -The magnet ring is radially-oriented with uniform radial magnetic performance, which can guarantee motor's silent operation and smooth torque output.

C: -Excellent corrosion resistance.

D: -The ED coating thickness of epoxy resin can be reached 20~35μm,

E: -The hot -extruded anisotropic radially-oriented ring magnets are mainly applied on EPS motors, servo motors, motors for electric tools and kinds of DC motors.

F: -High heat-resistance,with working temperature reaching 180ºC.

G: -The magnetizing poles and pole declination angle of the magnet ring do not have to be reserved, which can be realized through design of changing magnetization coils, with freely using and enough adjustment by customs.

H: -The magnetization waves of magnet ring can be customized and magnetized as square wave, sine wave and other special magnetization waves.

I: -The magnet ring without assembling can be realized multi-polarization and magnet pole declination, which is convenient for motor assembling.

J: -The magnet ring is nanometer crystalline structure with high density and ED coated by epoxy resin with excellent resistance, with thickness can be reached 20~35μm.

K: -The hot-extruded ring anisotropic radially-oriented ring magnets are mainly applied on EPS motors, servo motors, motors for electric tools and kinds of DC motors.

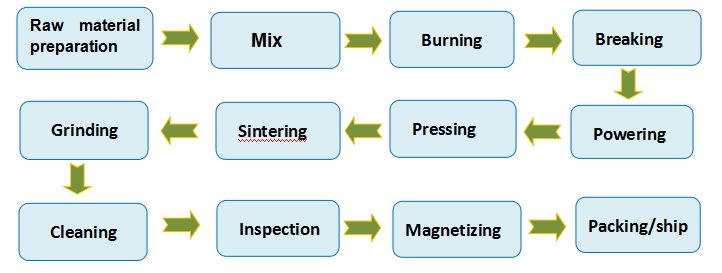

II. Production process

III. Manuafacturing Process and Magnetization

1. With dry process can produce isotropic & anisotropic magnets, the tool can be changed and developed easily.

2. With wet process only can produce anisotropic magnets,it is complicated to change the tool and the tooling charge is high.

3. Isotropic ferrite magnets can be magnetized in any direction.

4. Anisotropic ferrite magnets are all oriented in the manufacturing direction, and can be magnetized in the direction of orientation.

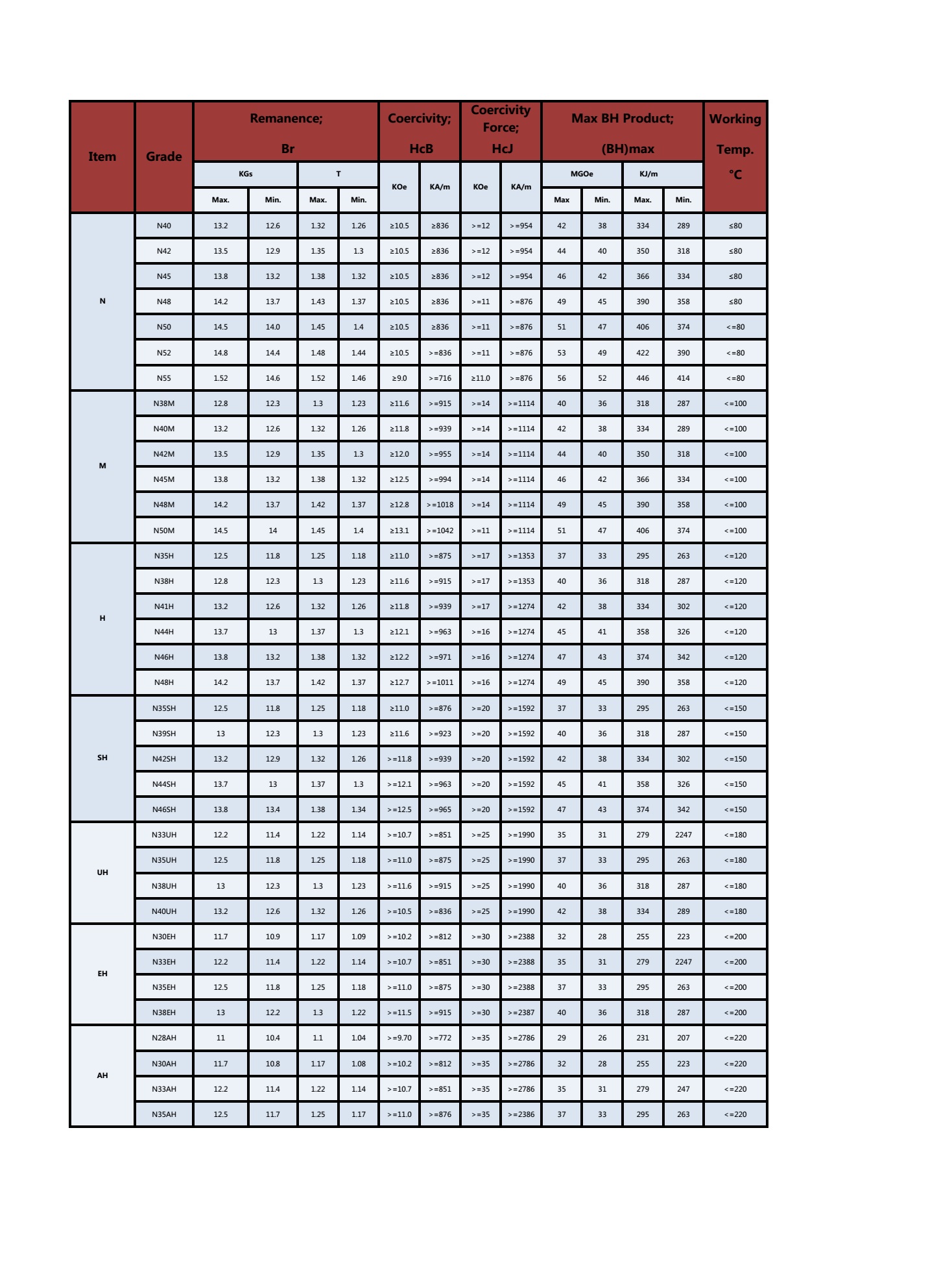

IV: Specification

Manuafacturing Process and Magnetization

1. With dry process can produce isotropic & anisotropic magnets, the tool can be changed and developed easily.

2. With wet process only can produce anisotropic magnets,it is complicated to change the tool and the tooling charge is high.

3. Isotropic ferrite magnets can be magnetized in any direction.

4. Anisotropic ferrite magnets are all oriented in the manufacturing direction, and can be magnetized in the direction of orientation.

CONTACT US

Chongqing Great Well Magnet Co.,ltd.

Address: D2-9-2, Golden Fruit Garden,Jiulongpo Dist, Chongqing.China,Chongqing,Chongqing

Contact Person: JOY LIU

Phone:86-23-89807080

Fax:86-23-68186641

© 2019 CHINA WAY. All Rights Reserved.Chongqing Great Well Magnet Co.,ltd.,Inc. All Rights Reserved. Sitemap. Sitemap.html