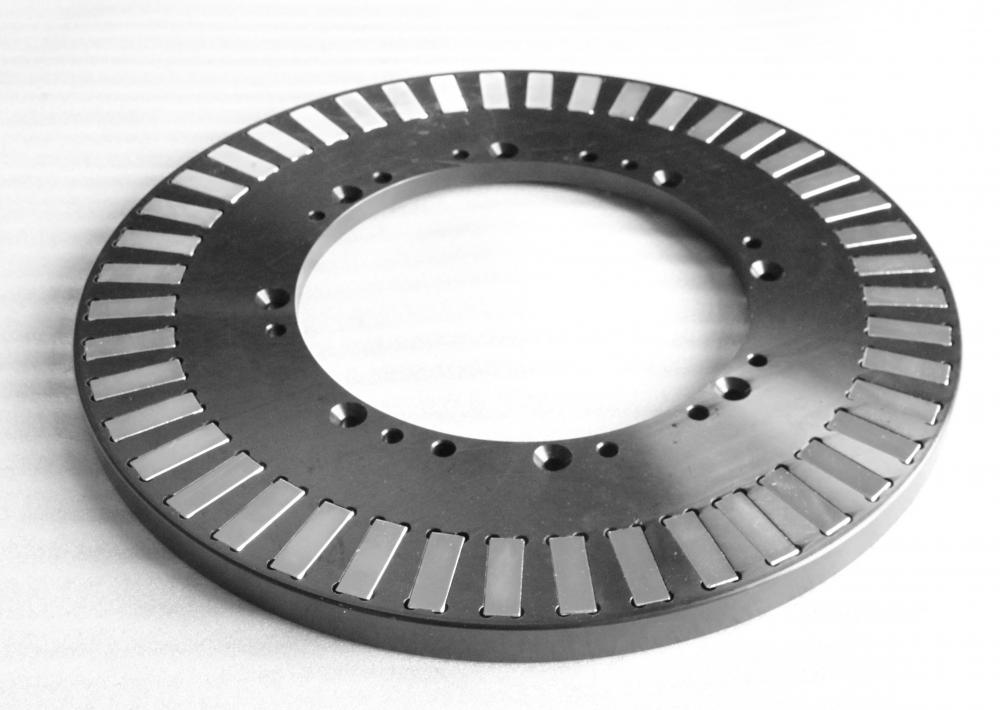

Magnet assembly for Linear Motor

| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 10 Set/Sets |

| Delivery Time: | 30 Days |

Basic Info

Model No.: GWM-0269

Additional Info

Packaging: Cartons, Pallets

Transportation: Ocean,Land,Air

Port: Shanghai,China

Product Description

Flat magnet linear motor

Linear motor is often described simply as a rotary motor that has been rolled out flat and the principles of operation are the same

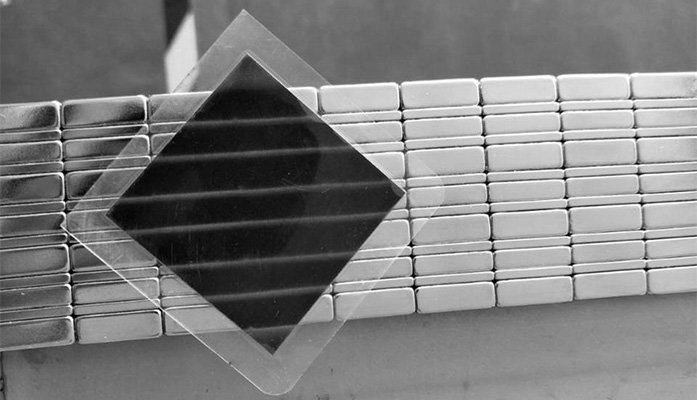

Forcer (rotor) is made up of coils of wires encapsulated in epoxy and the track is constructed by placing magnets (usually high-powerful neodymium magnets) on steel

Permanent magnet synchronous linear motion has excellent performance and it is widely used in the precision transmission system

According to the shape of the motor, it can be divided into U-type linear motor, flat-type linear motor and axial linear motor

We mainly produce U-type linear motor and flat plate linear motor

1. Materials

Magnet: neodymium magnet

Hardware part: 20# steel, martensitic stainless steel

2. Applications

U-channel and flat brushless linear servomotors have proven ideal for robots, actuators, tables/stages, fiber-optics/photonics alignment and positioning, assembly, machine tools, semiconductor equipment, electronic manufacturing, vision systems and in many other industrial automation applications

Why choose Linear Motor?

1. Dynamic performance

Linear motion applications have a wide range of dynamic performance requirements

Depending on the specifics of a system's duty cycle, the peak force and maximum speed will drive the selection of a motor:

An application with a light payload that requires very high-speed and acceleration will typically utilize an ironless linear motor (that has a very light moving part containing no iron)

As they have no attraction force, ironless motors are preferred with air bearings, when the speed stability has to be below 0.1%

2. Wide force-speed range

Direct drive linear motion deliver high-force over a wide range of speeds, from a stalled or low-speed condition to high velocities

Linear motion can achieve very high velocities (up to 15 m/s) with a trade-off in force for iron-core motors, as technology becomes limited by eddy current losses

Linear motors achieve very smooth velocity regulation with low ripple

Performance of a linear motor over its velocity range can be seen in the force-speed curve present in the corresponding datasheet

3. Easy integration

Magnet linear motion is available in a wide range of sizes and can be easily adapted to most applications

4. Reduced cost of ownership

Direct coupling of the payload to the motor's moving part eliminates the need for mechanical transmission elements such as lead-screws, timing belts, rack and pinion and worm gear drives

Unlike brushed motors, there is no contact between the moving parts in a direct drive system

Therefore there is no mechanical wear resulting in excellent reliability and long lifetime, fewer mechanic

Production line:

CONTACT US

Chongqing Great Well Magnet Co.,ltd.

Address: D2-9-2, Golden Fruit Garden,Jiulongpo Dist, Chongqing.China,Chongqing,Chongqing

Contact Person: JOY LIU

Phone:86-23-89807080

Fax:86-23-68186641

© 2019 CHINA WAY. All Rights Reserved.Chongqing Great Well Magnet Co.,ltd.,Inc. All Rights Reserved. Sitemap. Sitemap.html